To increase crane productivity, some sites dual cycle discharge and load work queues so that the crane is full in both directions.

If you are using Truck Control, dual cycling is configured differently. See Vessel load and discharge (dual-cycling) with Truck Control in Navis N4: Equipment Control Administrator and User Guide.

Dual cycling is defined as alternating vessel discharge and load moves for a bay. For example, once enough space is cleared on the discharge of a bay, a crane can start loading containers into the empty slots and retrieving discharges on the way back to the quay. This interweaving of load and discharge work queues can boost crane productivity.

In the Quay Commander window, you link work-queue blocks to plan dual-cycle crane operations for containers with current/future positions within the same bay.

You can dual-cycle work instructions equally for actual and projected containers. This is a great advantage when you have preplanned and sequenced projections but have not yet planned the actual load out.

To link work-queue blocks:

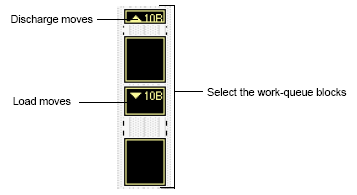

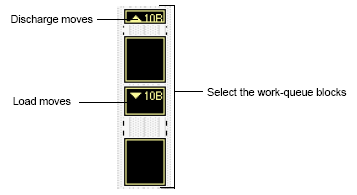

In the Quay Commander window, select a load work-queue block and discharge work-queue block with moves planned for the same bay.

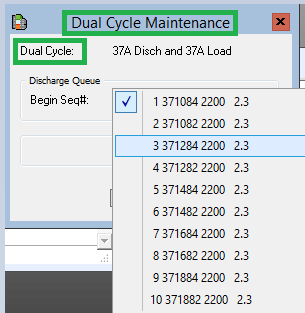

From the Actions list, select Dual Cycle selected queues.

In the Dual Cycle Maintenance dialog box, for the discharge work queue, select the point (work instruction) at which dual cycling will begin and click OK.

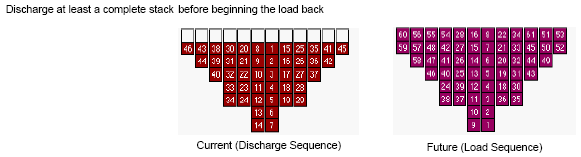

Load back begins after the work instruction you select has been discharged. Remember that you must discharge a complete stack before you can start loading back.

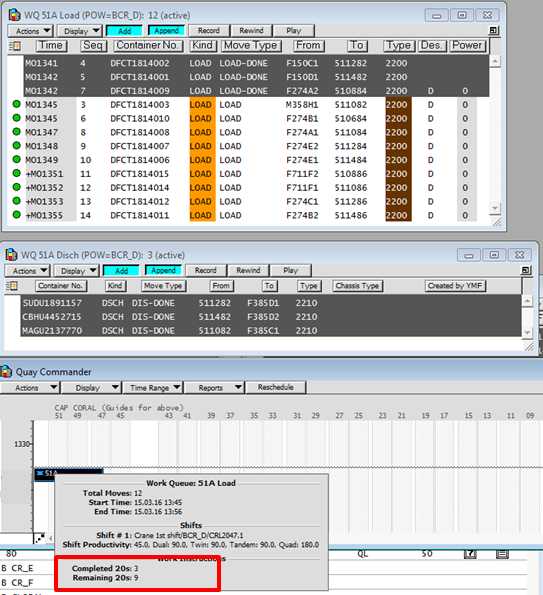

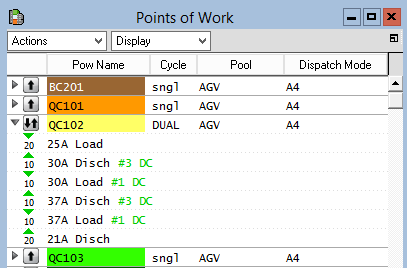

XPS displays the work queue with the higher work instructions count in the work-queue block. If the load queue has more work instructions than the discharge queue, XPS displays the load work queue. Similarly, if the discharge queue has more more work instructions than the load queue, XPS displays the discharge work queue. The following illustration displays the completed and remaining work instructions in dual cycle mode.

To view the dual-cycle work instructions displayed in discharge/load order, you need to sort the POW window accordingly.

In the Point of Work window, select Display and ensure Sort By Sequence is not checked.

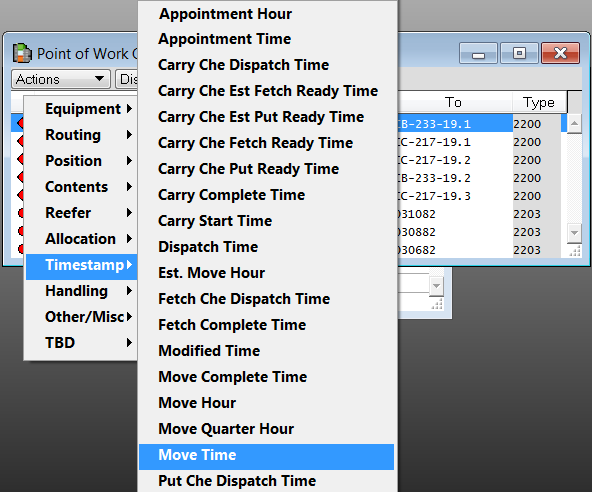

Select Timestamp  Move Time to add it as a sortable column.

Move Time to add it as a sortable column.

Sort the list by Move Time.

The jobs are now listed in pairs of discharges and loads, which accurately represents the order in which the jobs should be completed

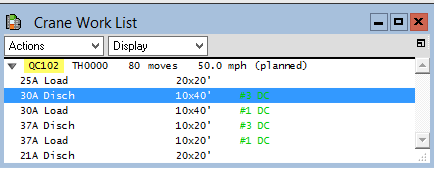

To view dual-cycle work queues for a crane, go to the Crane Work List window and Points of Works window. DC indicates that the WIs are part of dual cycle WQ.

When the last discharge move from the discharge queue is dispatched, the POW is changed back to single cycle mode.

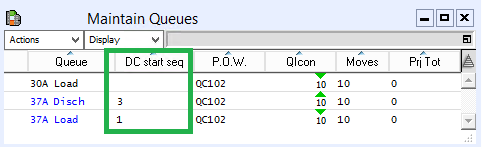

To view the dual-cycle sequence number go to Maintain Queues window.